Why You Should Try Ferrite Magnets With Us?

We are a company that create value for our customer’s projects. We always aim at producing and delivering quality neodymium magnets that meet all your needs.

With 10+ years of manufacturing experience in the magnet industry, we are producing high-end magnets for Europe and US customers.

What We have:

- Self-developed key equipment

- Unique manufactruing process

- Energetic R&D department

- Full scale production

- Integrated industry supply chain

- High consistency quality magnets

Ferrite Magnet Shapes

Ferrite Magnets are usually made into different grades, shapes and coatings for different purposes. Here are some of the ferrite magnets that we produce for our different customers.

Basic Specification of Ferrite Magnet

Grades:

The two main grades used today are C5 (also known as Feroba2, Fer2, Y30 and HF26/18) and C8 (also known as Feroba3, Fer3 and Y30BH).

Shapes

Magnets are usually made into shapes such as Block, Disc, Rod, Ring, Segment, Balls, and some with countersinks. These are for different types of applications.

Our Advantages

Technology Advantage:

Depending on advanced R&D team and machining technicians, we can surpass our competitors in the stability of quality and superiority of property.

Delivery Advantage:

The lead time must be 2-5 days quicker than industry average because of more fexible machine process control.

Price Advantage:

The price is 5-10% cheaper than industry average because of an excellent and efficient management system.

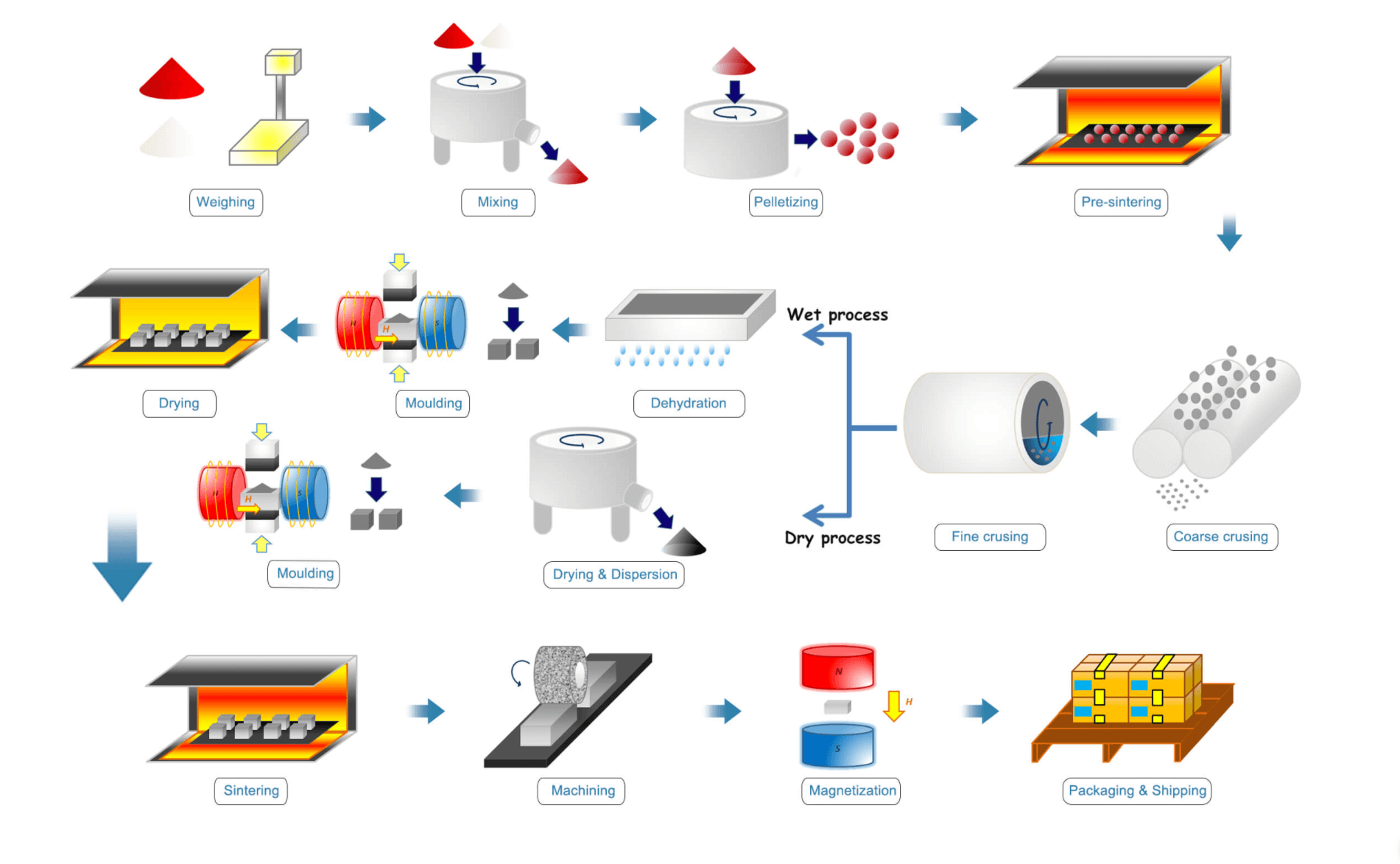

Manufacturing Process of Ferrite Magnets

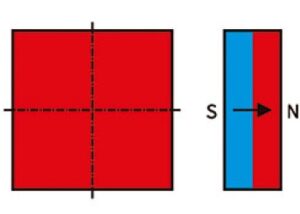

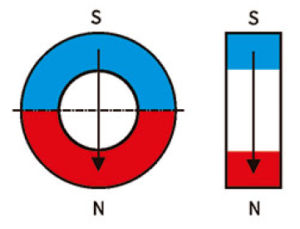

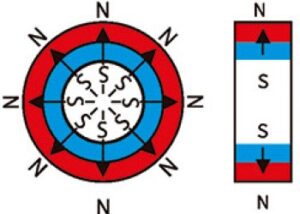

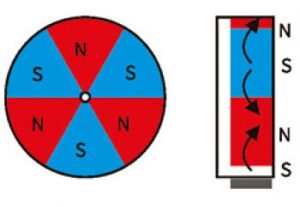

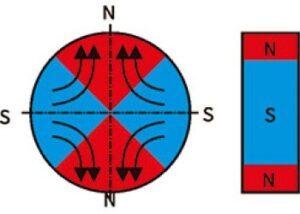

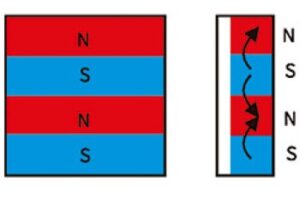

How Can The Magnets Be Magnetized

Magnetized through depth

Axial Magnetized

Diametrial Magnetized

Axially magnetized in segments

Radially magnetized

Multipole magnetized in segment on the surface

Multipole magnetized in segments on outside diameter

Multipole magnetized in segments on inside diameter

Magnetized laterally on the face

Application of Magnets

Ferrite magnets, also known as ceramic magnets, are commonly used in various applications in the past several decades, such as the loudspeaker, motor, and generators.

Take Your First Step to Boost Your Business

Buying the most suitable magnets can be fast and easy for your projects.